Laser welding protection Cabin

Interested in this product?

At PhotonWeld, we understand that every project is unique. For products without a listed price, we invite you to reach out and share your specific requirements. Whether it’s dimensions, sizes, or any particular preferences you have in mind, our team is here to assist you in creating a tailored solution that meets your exact needs.

Contact us for a personalized quote!

PhotonSafe® Laser Protecting Cabin

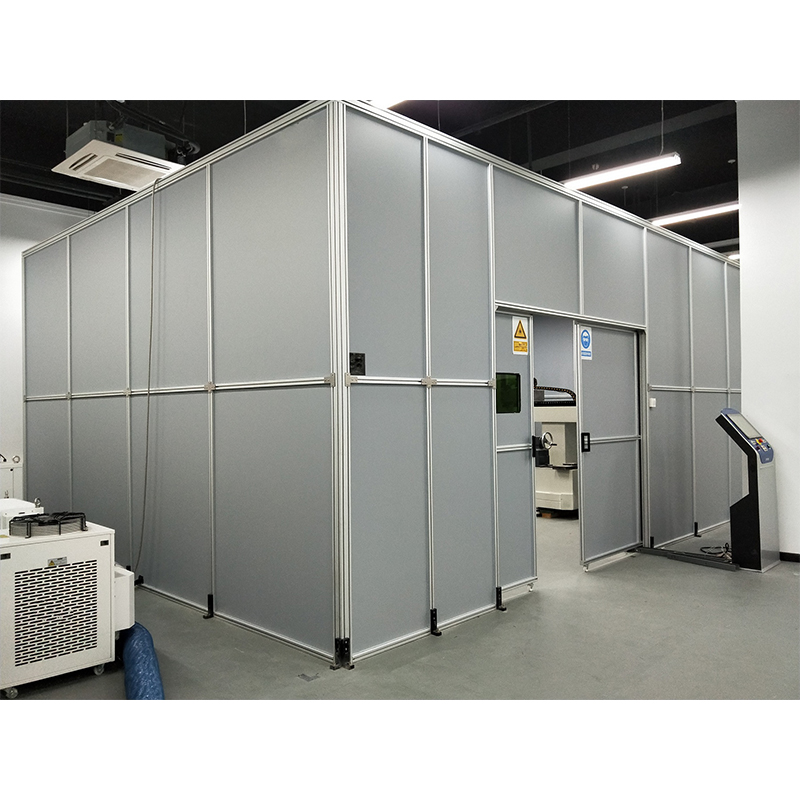

PhotonSAFE®: Non-Combustible Laser Welding rooms - Laser Safety cabins

The best way to safeguard a class 4 laser environment might be to enclose the whole area on a large scale within a cabin. This kind of cabin solution is frequently used, particularly in the case of laser power ratings in the multi-kW range (as used in laser material processing). It is possible to enclose a laser application locally (for example, on an optical table) or within a room-sized cabin.

Extraction systems, as well as associated vent holes, can also be implemented.

The laser safety cabins are designed in a way, that for applications with class 4 lasers, the environment is properly protected and full fills the class 1 conditions according to EN 60825-1 and OStrV.

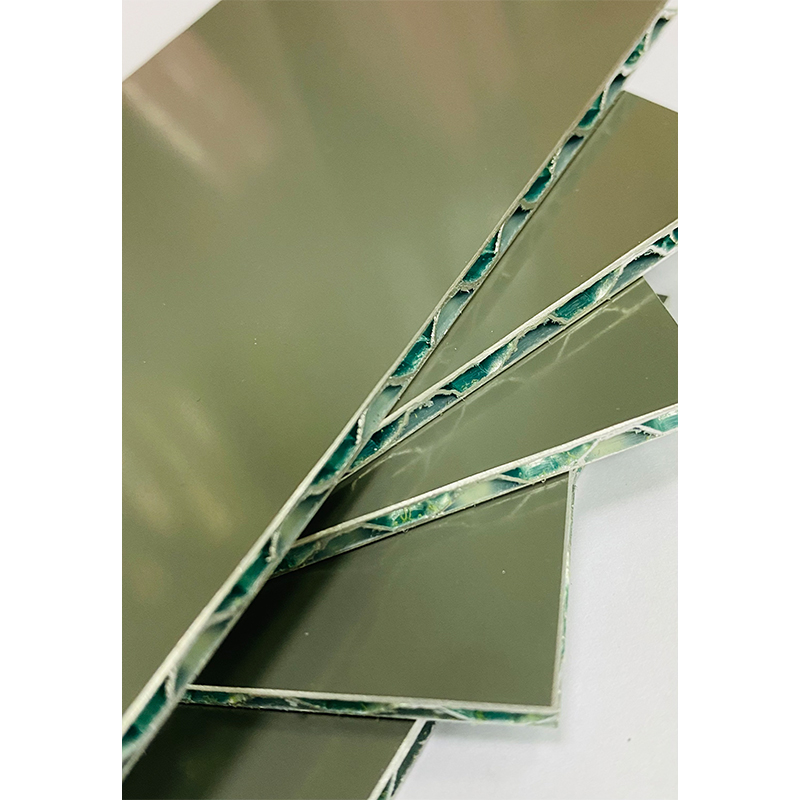

All materials used are all "non-combustible" as they received all an Euroclass A1 rating under BS EN 13501-1

A1 materials are completely non-combustible while A2 materials have very limited combustibility. While A1 materials have no contribution to fire, A2 materials have limited contribution to fire. Stringent tests must be passed in order for construction products to reach a Class A rating. As above, A1 rated products do not require additional safety tests given they are completely non-combustible. Examples of these materials include aluminum, steel, natural stone, concrete and porcelain.

Lasermach’s design allows for easy installation as our lightweight panels with fire ratings Class A1 come in 800-1000-1200 mm width and are assembled on site. Installing this way minimizes the need for riggers and costly equipment needed to install full wall panels.

PhotonSAFE® is the solution for providing an enclosure for light-based welding applications, and is available in standard and customized versions. Lighting, bottle securement, fume extraction, power management, and table integration are all features available on the PhotonSAFE welding booth system. Interlock protection is standard on the PhotonSAFE and can be integrated with the Photonweld laser welding (or other brands) machines.

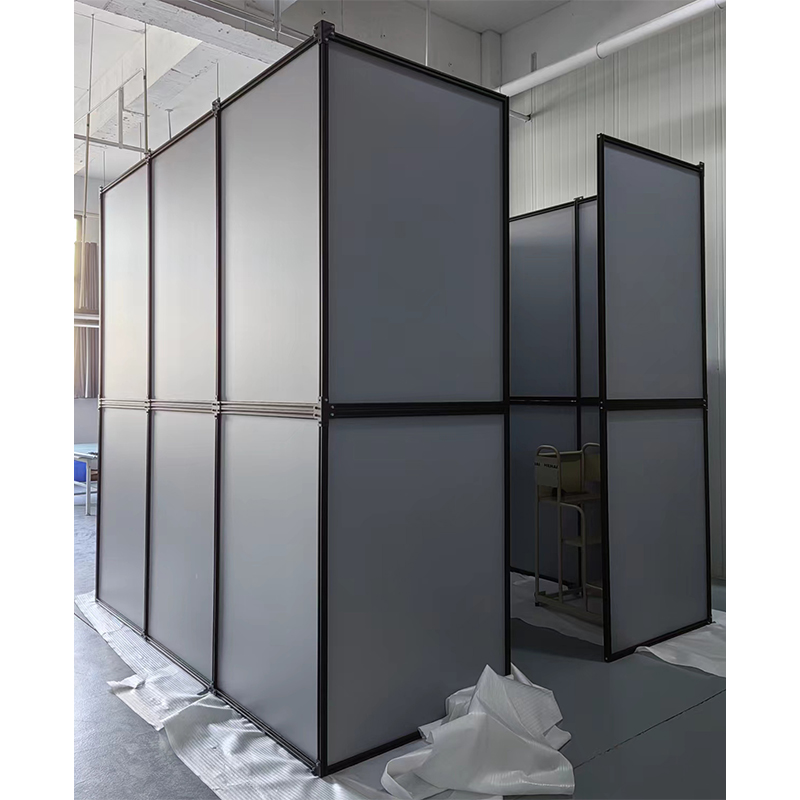

Modular Laser safety cabin

The best way to safeguard a laser environment according to EN 60825-1 and OStrV is to enclosure the whole laser area. Especially in the field of laser material processing with laser powers up to the kW range, this is a very common way to proceed. The cabin will then be designed in a way, that the laser area is still accessible.

The laser safety cabins can be equipped with an Interlock Control System. Additionally, one or more windows can be integrated to monitor all operations in the cabin. The modular concept of the laser protection cabins thus offers a very cost-effective and simple way of living around a laser system while fulfilling the international regulations for laser safety. Outside this laser protection cabin, the area can be designated as laser class 1. This ensures a workflow without disruptions and without additional protection requirements.

- Properties of the laser safety cabin/enclosure:

- Flexible cabin concept due to modular design

- Fast installation of the laser protection cabin

- Variable design

- Single-shell wall system

- Material: Alu-profiles

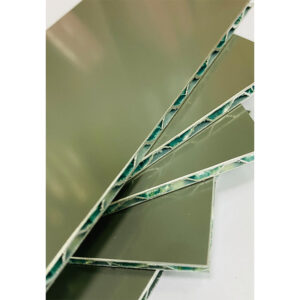

- Side walls and roof made out of laser tested and approved material

- Wall segments will be opaquely inserted in the Alu-profiles

- Access via swing-doors, sliding doors, gates or flaps

- Ceiling light (LED modules, 1800 lumen, 230 V, 18 W, neutral white, 4000 K or other)

- Integration for laser safety windows, interlock-control systems, warning signs, extraction systems or cable feedthrough possible

The assembly on side can be offered as an additional option. Furthermore, we offer a final expert inspection (survey) of the installed enclosure regarding laser class 1 according to EN 60825-1.

Reviews

There are no reviews yet.